- Certifications

-

- Subscribe

-

Get email updates on new products

- Contact Us

- Sales Center: Sales31@finehope.com Address:466Jiu-tian-hu Road Xinglin Jimei Xiamen, P.R. China 361022 Contact Now

PU Roman spherical top edge protector cover, PU protective side cover, PU Roman head the ball, Polyurethane Foam Materials Suppliers

- Name: PU Roman guard side cover, polyurethane foam top cover building materials spherical Edge Protectors

- Type: building materials - spherical edge protection cover

- Material: PU Polyurethane - wood Foam

- Density: 200-250kg / m3

- Shape: customized according to customer product design

- Surface Treatment Color: Painted white, the color can be customized according to customer requirements

- Packaging: standard carton

- Payment Terms: 30% deposit, payment and delivery.

- MOQ: 1,000pcs

- Shipping Location: China • Fujian • Xiamen

- Meet the certification: RoSH, REACH, EN71-3, phthalic 6P

- Other: China OEM and processing factories, specializing in the production of PU products, including product parts (iron, wood, plastic, etc.).

First, the product description

1. Features

PU Roman spherical top edge protector cover PU protective side cover PU Roman head the ball Polyurethane Foam Materials

Rigid foam features:

1. High strength, light weight, good flexibility and toughness;

2. The insulation effect is good, no distortion, no shedding, durable and strong;

3. Has the characteristics of wood, planing, nails, saws;

4. modeling diversification, according to customer demand, custom mold;

5. The surface color can be processed according to customers like the color;

6. wood effects: natural wood pattern effect is clear, elegant and luxurious;

7. Anti-flame retardant, through a special process, can reach no spontaneous combustion, no combustion of the properties;

8. filler reinforcement can be placed;

1. furniture industry: frames, bed frames, frame, wardrobe / cupboard / decoration, chair / chair legs carved doors;

2. The construction and decoration materials: strip, lights junction box, a small statue / sculpture, carving pillars;

3. Automobile industry: interior, rear luggage cover, automobile row cover, trunk lid hard truck, trailer side / visor and the like;

The sports equipment: hockey sticks, skis, skid plate, a fish, racket handle;

5. insulation: refrigerator, freezer within rigid foam insulation board / incubator;

6. Other general purpose: carved cedar carved picture frames, trays, computer / television / radio housing, engineering parts, decoration materials;

Second, with regard us

1. Introduction

- We are a leading manufacture of molded polyurethane products manufacturer, was established in 2002. Our products are mainly exported to European and US markets.

- We have a professional production of polyurethane products top-quality requirements for the goal. The main reason customers choose our fancy our broad R & D capabilities and with international brand companies and ensure long-term experience with shipping quality.

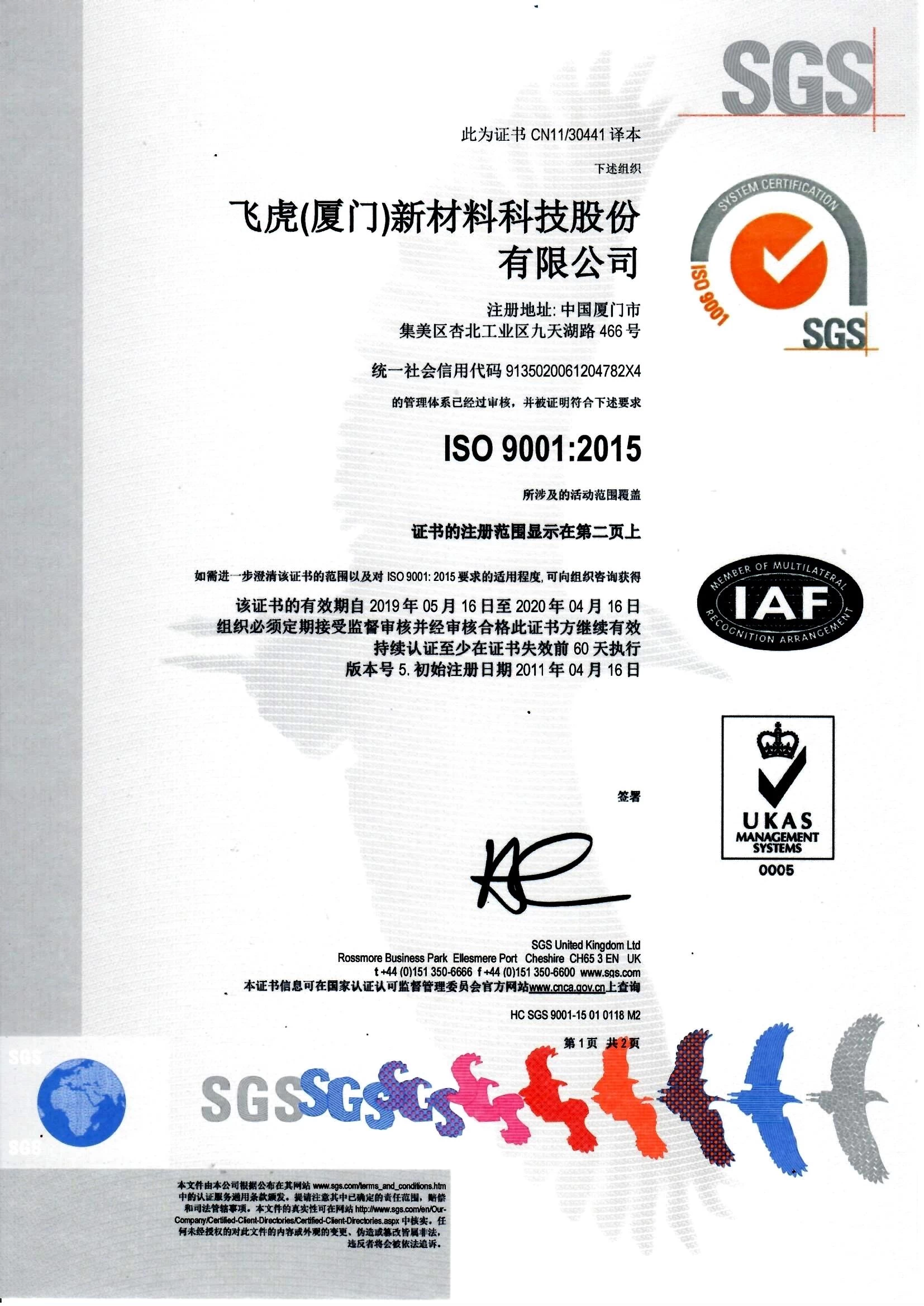

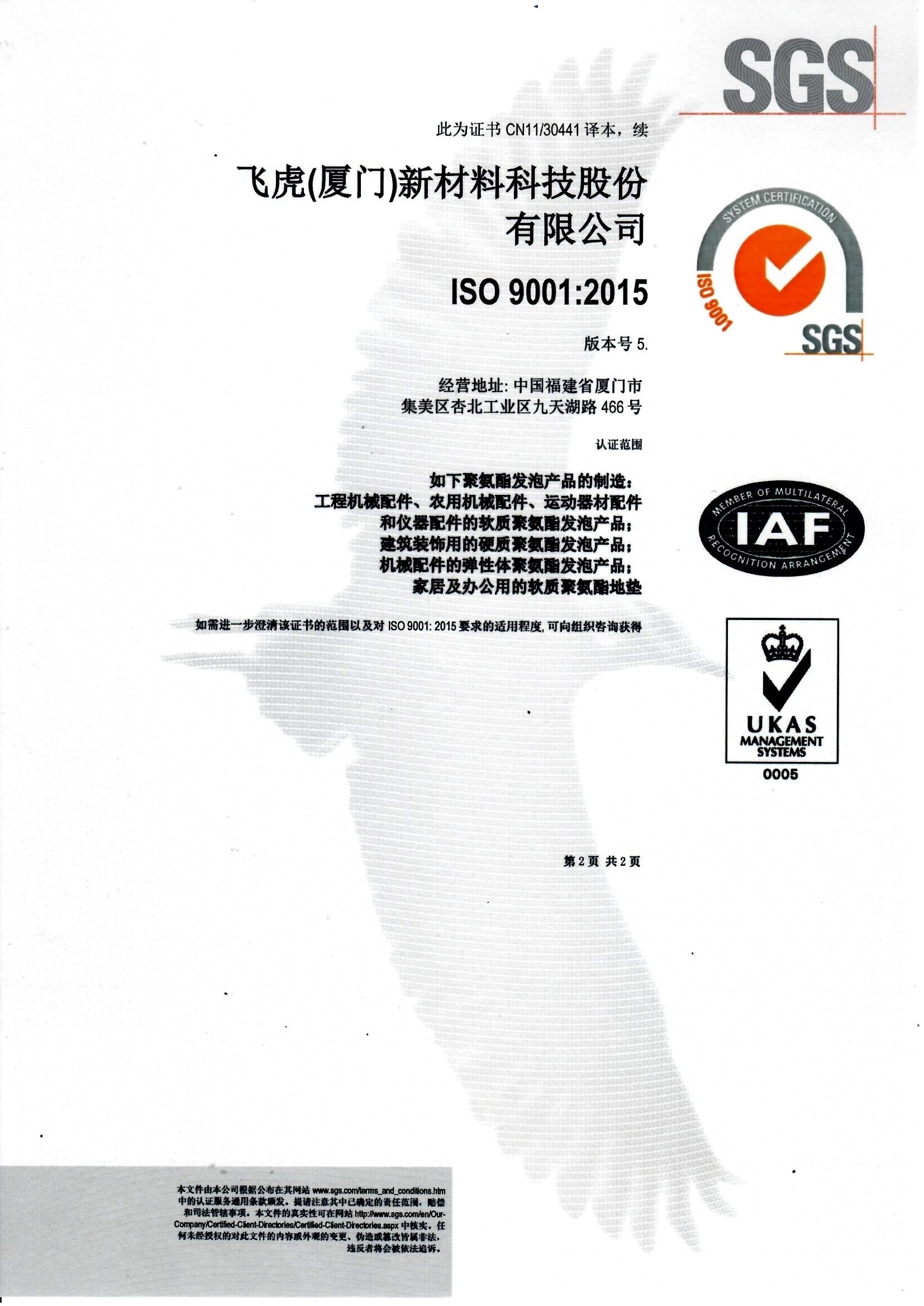

- Division I after the Swiss SGS ISO9001-2008 certification, in accordance with TS16949 system for quality control. Lean is we have been pursuing the goal to reduce waste, create additional value, sustained commitment to help our customers control costs and create additional value.

2, our brand customers

Located in various regions and industries the Americas, Europe, Asia ...... welcome your visit, thank you!

3, our advantage

A. Quality management through the company ISO9001, ISO / TS 16949 quality management system continued to promote, maintain and regularly reviewed to ensure their full, appropriate and effective operation;

ISO / TS 16949 five core tools: effective use of APQP, FMEA, MSA, SPC, PPAP, so that our quality control and overall management level have been greatly improved, and ultimately to meet customer requirements.

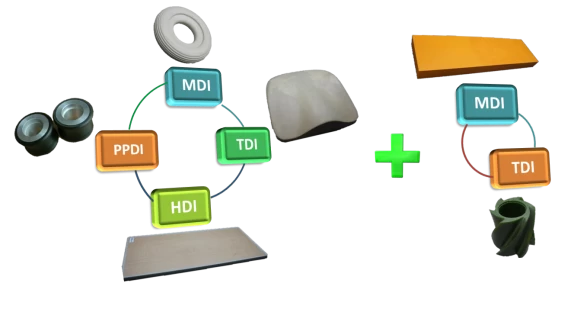

B. materials research and development of polyurethane material has a professional R & D team has been put into products, including MDI, TDI, HDI, and PPDI and other polyether, polyester systems formula, covering all polyurethane systems formulations.

C. improved equipment for production equipment has the ability to self-improvement and self-designed research Jidoka mold fixture, lean from Dong line.

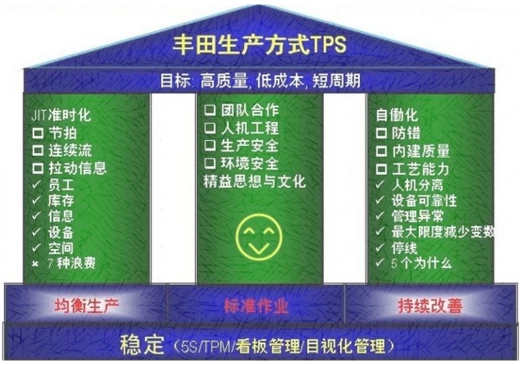

D. Toyota's lean production using TPS lean management model to improve production efficiency, reduce waste and reduce costs.

4, our production

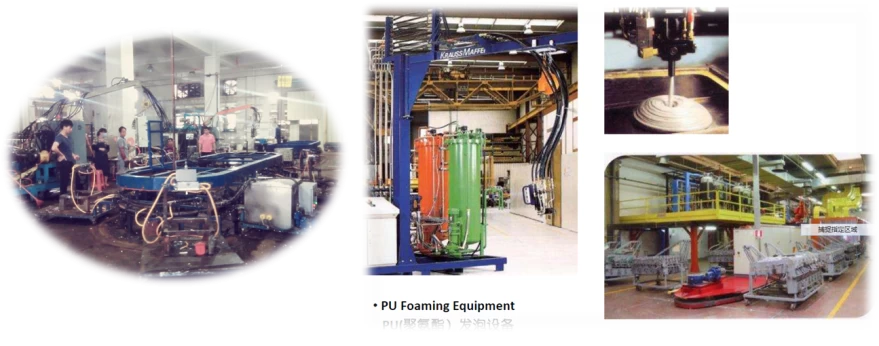

- Has PU industry's most advanced production equipment, including KraussMaffei machines and other production materials of different PU products of high / low pressure perfusion machines;

- automated assembly line operations, including perfusion lines, painting lines, polishing lines, since shaken mold lines.

- have independent mold design, production, the ability to innovate, and a wealth of experience in the design and processing of metal, plastic and other parts of the PU;

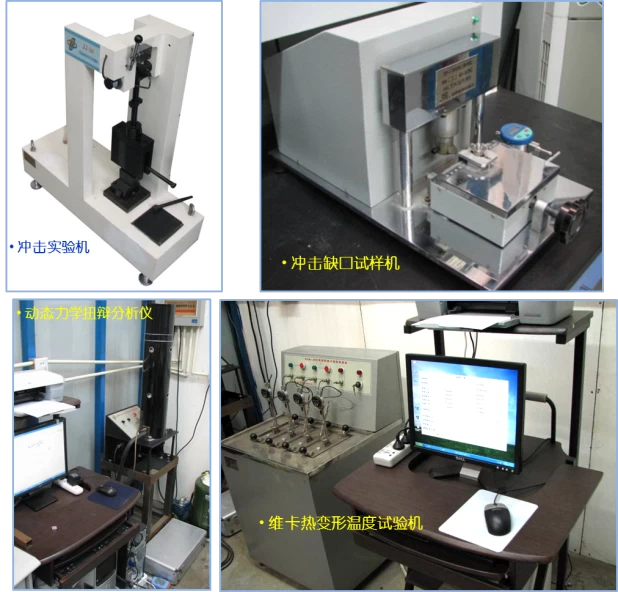

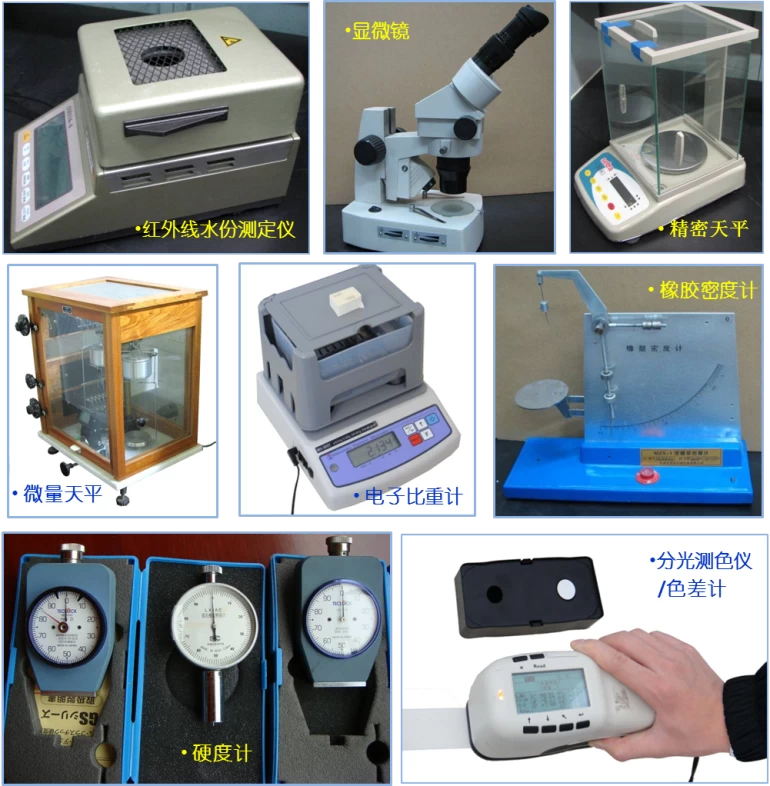

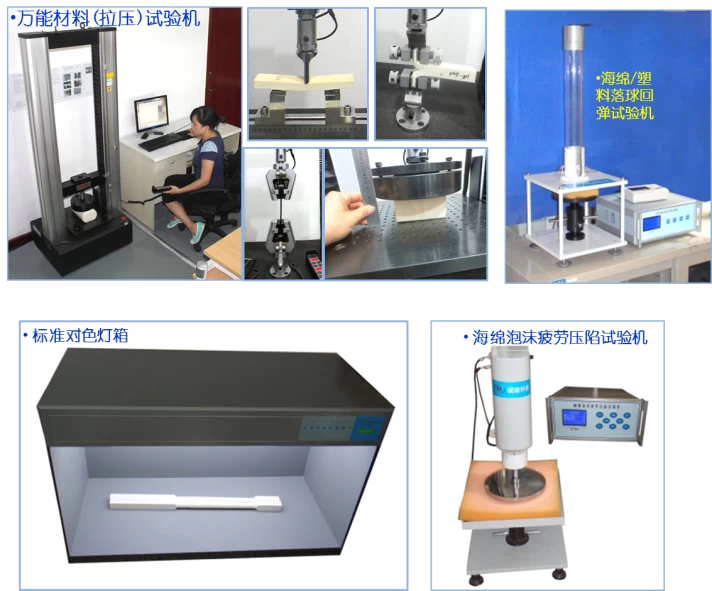

5, our testing equipment

- Finehope PU material has a range of testing equipment, and dedicated quality assurance system and quality control engineers.

- Finehope will carry out the testing product analysis, mechanical analysis products and materials, and ultimately develop a test product. Thereby reducing the quality standards disputes between customers and manufacturers.

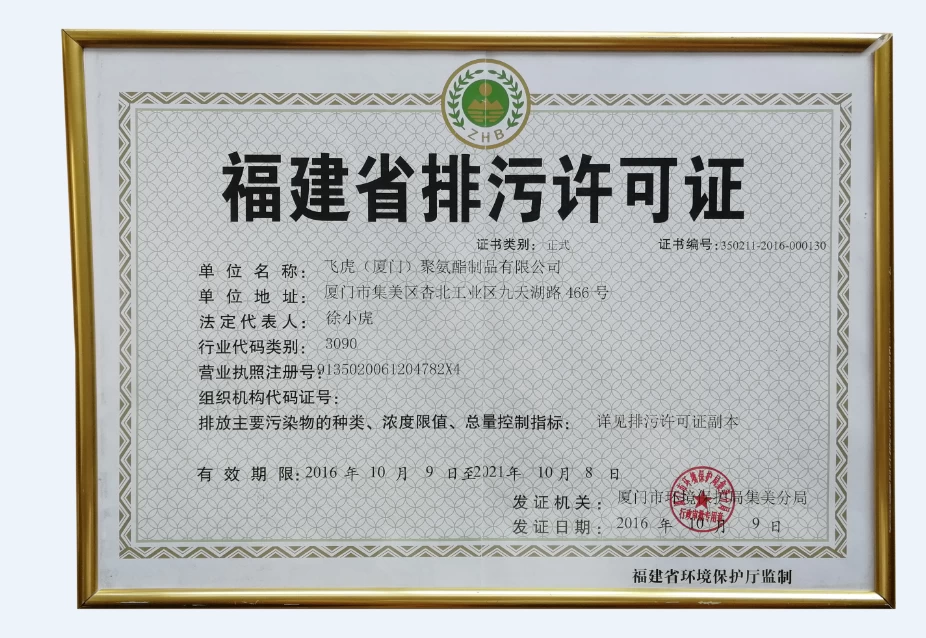

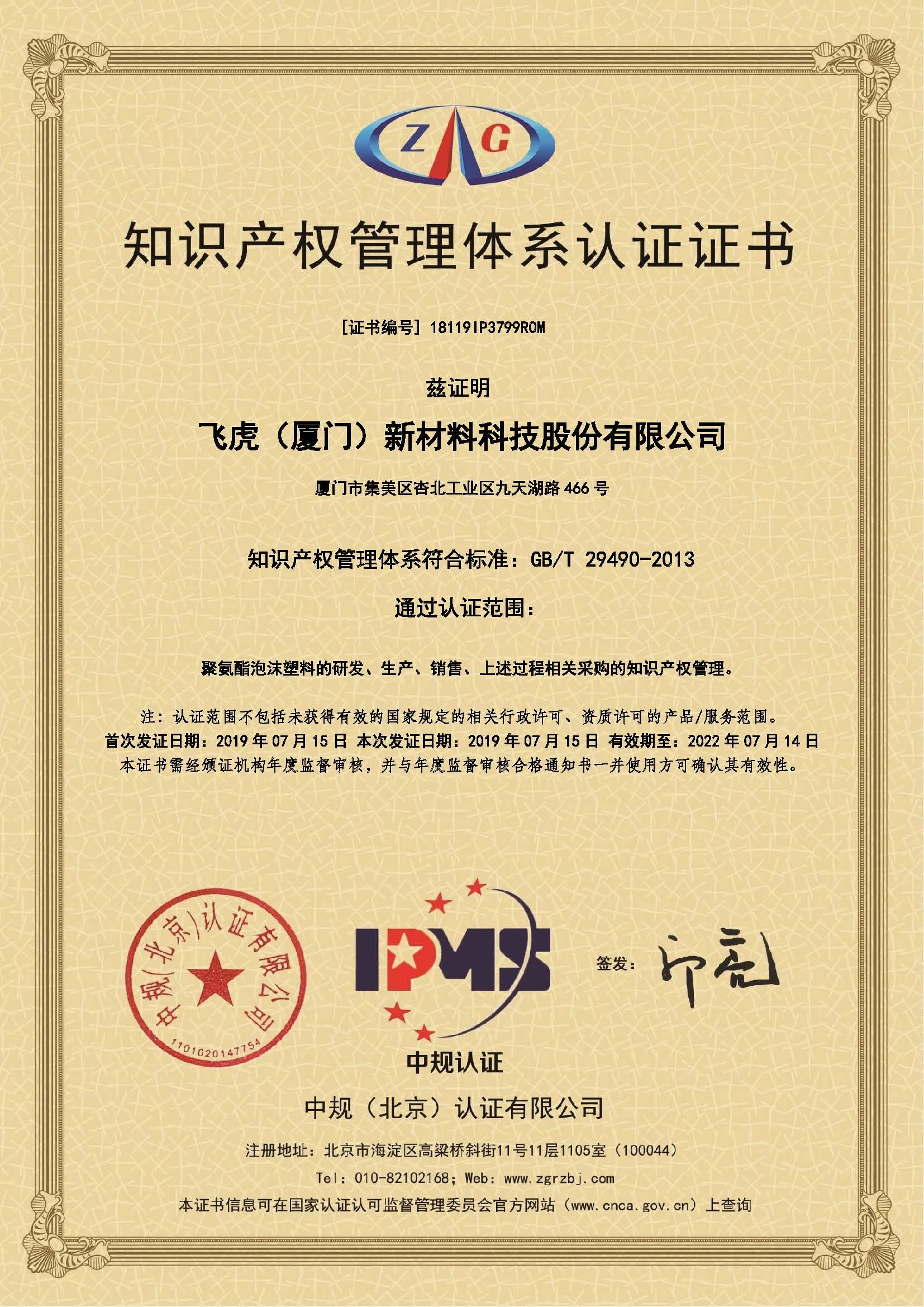

6, we certificates

- Finehope as Huaqiao University, Xiamen University and the polyurethane product research and postgraduate training base station.

- Finehope domestic high-tech enterprises, with a number of domestic and foreign patents polyurethane intellectual invention.

- Finehope passed ISO9001 certification, Alibaba, Alibaba is also a boutique company Prudential enterprises.

Third, FAQ

1) Why did you choose Finehope

Finehope is China's most professional manufacturer of PU, has a professional R & D team, advanced PU production equipment, professional testing equipment and perfect quality management system. Division I and CAT, FIAT, TVH, GGP and other famous enterprises have 12 years of experience of cooperation. Division I provide them with one-stop service from the production and customization to meet their needs.

2) Select Finehope benefits

Reduce your time, reduce personal problems, reduce costs (explicit and implicit costs).

3) the product delivery cycle

Upon receipt of the deposit and the completion of 30 days to complete mold production, preparation and equipment without queuing period 10 days (depending on order quantity).

4) Product of transport

Qiyun, shipping, air transport (FedEx / UPS), depending on customer requirements.

5) How to track goods transportation

If the ocean bill of lading number will be provided to the customer, if it is air transport will provide fast waybill number.

6) How good product quality control

Quality first, to provide customers with high quality products is our mission. A professional team from beginning to end, good product quality control:

• All the raw materials, parts prior to production must undergo a rigorous inspection;

• All workers must undergo pre-production formal training;

• All products must pass strict control and inspection in the production process;

• All products must be checked before shipping again.

Fourth, contact us

For more information, please contact us. I am Feiyan Zeng, welcome your visit, thank you!

Phone: + 86-592-6661766

Fax: + 86-592-6282029

Miss Zeng Email: feiyan@finehope.com

English Web site: www.finehope.com

Chinese Web site: http: //finehope.1688.com/

Tel:86-592-6661766

Contact Person:Sales

PDF Show:PDF