The shipment volume of Covestro polyurethane composite photovoltaic module frames has exceeded 3 gigawatts

Covestro announced that the cumulative shipment of photovoltaic modules carrying its innovative polyurethane composite material frame technology has exceeded 3 GW, equivalent to about 5 million conventional photovoltaic panels being put into use around the world, with a laying area covering more than 1100 standard football fields. This achievement demonstrates the market's recognition of this innovative technology.

As the second largest cost component of photovoltaic modules after solar cells, traditional aluminum alloy frames typically account for 10% to 15% of the total module cost. Against the backdrop of cost pressures and high aluminum prices in the current photovoltaic industry, polyurethane composite frames have shown significant advantages. Baiduo of Applied Innovation ® The module frame of polyurethane composite material has the characteristics of high strength, corrosion resistance, and excellent insulation performance. It can not only effectively improve the performance and service life of photovoltaic modules, but also help photovoltaic enterprises to get rid of the impact of aluminum price fluctuations and achieve cost reduction and efficiency improvement. In addition, Baido ® The carbon footprint of polyurethane composite from cradle to gate can be reduced by 85% compared to the original aluminum profiles used in traditional frames.

Akhil Singhania, Global Head of Special Products at the Customized Polyurethane Business Unit of Covestro, said, "Through more than ten years of innovation accumulation and continuous polishing, we have not only opened up a new path for cost reduction and efficiency improvement in the photovoltaic industry, but also injected new energy into its sustainable development. The milestone of achieving 3 gigawatts in rapid mass production in just over two years fully reflects that polyurethane frames have risen from an 'innovative experiment' to an 'industrial necessity' to enhance competitiveness

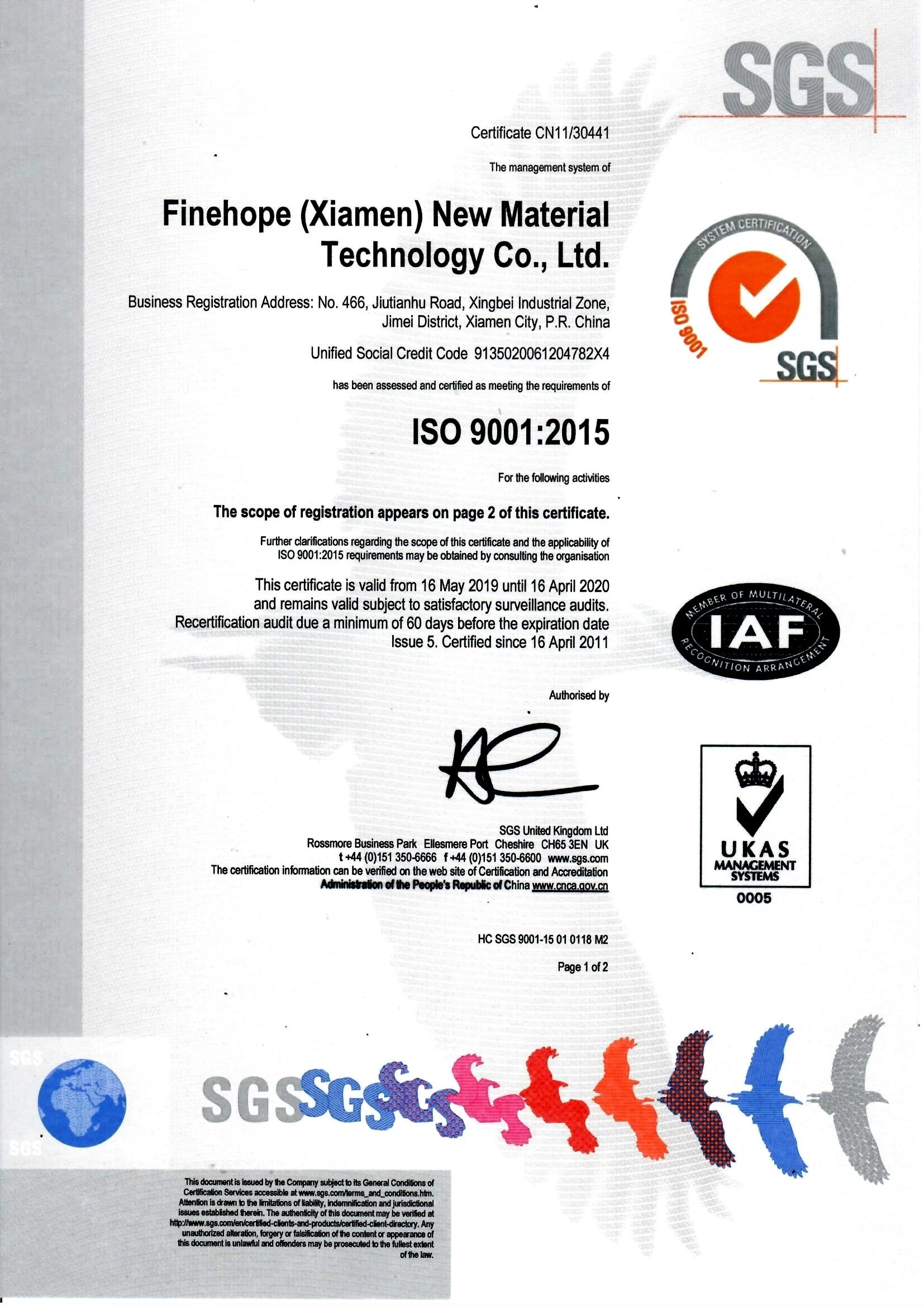

China's photovoltaic module production has been ranked first in the world for many years. In 2023, when the photovoltaic industry faced unprecedented cost pressure, Covestro's composite material frame application achieved a key breakthrough, quickly gaining market favor with outstanding advantages and dual authoritative certifications (T Ü V Rheinland and T Ü V S Ü D). In 2024, multiple component companies have adopted Baido for large-scale production ® The components of the polyurethane composite frame have achieved an important milestone. According to the International Energy Agency's "Renewable Energy 2024" report, it is expected that from 2024 to 2030, the global installed capacity of renewable energy will exceed 5520 gigawatts, of which nearly 80% will be solar photovoltaics. The emergence of more cost-effective and sustainable innovative composite material frame technology is timely and has great potential.

In addition to polyurethane composite frames, Covestro has also developed Desmodur for the photovoltaic industry ® Ultra N 31890 BA aliphatic fast drying curing agent. This locally developed product is suitable for photovoltaic backsheet coatings, with a drying speed nearly three times that of standard curing agents, which can significantly improve backsheet production efficiency and help the industry save energy and reduce carbon emissions. At the same time, the product has better UV aging resistance and hydrolysis resistance, providing protection for the long-term use of the backboard.

In addition, Covestro can also provide polycarbonate material solutions that combine lightweight and excellent mechanical properties, providing reliable protection for photovoltaic, energy storage, charging piles, and various new energy equipment casings. Even in harsh outdoor environments, it can achieve long-term stable operation. Under the trend of integrated development of light storage and charging, Kesi Chuang polycarbonate solutions can also highly integrate components and functions such as lighting, touch, display, and electronic circuits, helping to create lightweight and intelligent surfaces for light storage and charging systems. In addition, these solutions can also provide low-carbon versions with stable global supply capabilities, helping enterprises create differentiated advantages and promote green overseas transformation.

It is reported that from June 11th to 13th, Covestro will showcase its latest polyurethane composite frame application cases and new energy equipment material solutions at the "SNEC PV+18th (2025) International Solar Photovoltaic and Smart Energy (Shanghai) Conference and Exhibition" B Hall 260 exhibition area.